Part 1: What goes up should never come down (published April 2012)

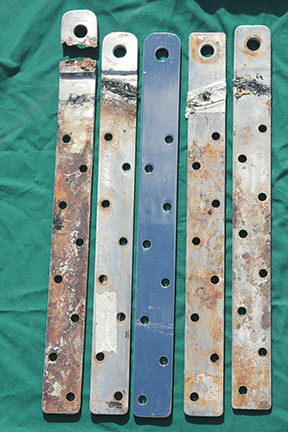

From a soft breeze and tropical sunshine, the sudden blast of wind dimmed the horizon and stung us with horizontal pebbles of cold rain. With eyes squinched against the precipitation, I went to turn the wheel downwind to ease the pressure on our old sails. I heard a pop, then watched the top of the mast wobble for a moment before gracefully folding to starboard, creasing just below the spreaders. My wife Rebecca was below and did not realize there was a problem until she heard my pleading voice. The port upper shroud chainplate had snapped due to

serious internal corrosion hidden by its shiny exterior. Such is the insidious nature of stainless steel.

DESTINATION

After organizing the mess and stabilizing the mast, we had to make the decision of what destination in this remote corner of the Pacific we would limp to so the adventure of replacing the mast could begin. We wanted to avoid the mistake of one dismasted yacht owner who diverted to a remote cruising destination in Tonga, where a charter company is located. After a year’s wait for their new mast to be delivered, it arrived damaged. They had to reorder.

We needed a port with good shipping and mail service from the United States, a place to lay out a mast and a crane to lift it. Six hundred forty miles to the north, Majuro in the Marshall Islands had what we needed plus well stocked hardware stores. A cruiser installing a new mast needs countless drill bits, thread taps, screws, sealants and unforeseeable items. With our jury rig and plenty of fuel for our diesel engine, we would force our way there.

TITANIUM

Fully re-rigging from the mast step and chainplates to the mast tip, I saw no reason to duplicate a problem and install more stainless steel

chainplates. Titanium has always had a special solid sound to its name.

Named after the mythical strong men of Greece, grade 5 titanium has a yield strength that is 3.5 times stronger, yet little more than half the weight of 316 stainless steel. Sometimes Grade 2 titanium is used for marine applications due to its lower cost, but its yield strength is only 15% greater than that of 316 stainless steel.

Titanium is in use everywhere. It’s the white pigment in paints and bright white paper, and it’s the white that sailors like to smear on their noses on a sunny day. Drill bits are coated with golden titanium nitride. The landing gear of large aircraft is made of titanium, and architects specify titanium where no other material will endure. Titanium is widely used, but it is interesting to note that only five percent of mined titanium is turned into metal.

What is most used for marine applications is Grade 5 titanium, Ti-6A-4V, which is 90% titanium, 6% aluminum and 4% vanadium. On a sailboat, titanium metal is impervious to sea water. It will never corrode, pit or be affected by electrolysis or galvanic corrosion. Titanium is equally resistant to chlorine and acids. On a yacht sailing the world, titanium is an install-and-forget metal.

Allied Titanium (www.alliedtitanium.com) made our new chainplates, clevis pins and mast tangs. Although more expensive than stainless steel, the cost of titanium has dropped tremendously, making it affordable for cruisers. Money we do not pay to an insurance company is money far better spent on the assurance of chainplates and fittings that will never fail us again. We sent our old chainplate and fittings to Allied Titanium so they could draft and create the UPD (Unique Product Description) Sheets. Alternatively, we could have made a paper tracing of those parts, specifying the thickness of the metal, hole sizes and finish desired, either polished or sandblasted. Once approved by us, the UPD Sheets were sent to their production facility.

While our titanium parts were being made, the next step was to research mast builders with good reputations on the West Coast of the U.S. or other areas of the Pacific rim. The mast builder must have close proximity to a major shipping port where a shipping consolidator would have container service to our location in Majuro.

THE SPAR AND STAYS

Ballenger Spars in Watsonville, CA (www.ballengerspars.com) has a good reputation and is close to San Francisco, where the freight company we would use is located. Having Ballenger deliver the finished mast to the freight consolidator saved us more than $500 from having the freight company fetch the mast and transport it back to the container. As the mast was being constructed, we ordered parts that were too long or too hazardous to be shipped in the mail and had them loaded into the container that would eventually carry the mast.

You would think the owner of a popular model boat could simply call a mast maker and tell him to make a mast and ship it out. It’s not that easy. Mast makers keep files on masts they have built, but Ballenger did not have specifications for a Valiant 40 mast. In any case, masts can change according to a yacht owner’s whims. It was left to us to supply accurate measurements from our old bent and mangled spar.

A long list of details must be mapped before a mast can be constructed. Winch pads, shroud attachment points, halyard entrance and exit points, spreader location, tang bolt sizes and locations, etc. all had to be detailed. It is standard practice to measure and design a mast from the top down. The best we could do was measure from the remains of our mast from the bilge up, through a deck, over a bent mast section and guesstimate the rest. Doing some mathematics, we developed the required top-down figures. But with all this labor, it seemed we were creating potential problems rather than developing accurate plans.

Fortunately, we were able to contact the designer of our boat and have original mast drawings and specifications sent to Ballenger. But those were 30-year-old plans. Roller furling head sails, winch placement and other modern thinking had to be incorporated into those plans with a mind on our tentative measurements. A blizzard of emails flew. It became a full-time job for Rebecca to communicate with Ballenger and the suppliers of our roller furling, mast track, titanium parts, etc. to coordinate the creation of our new rig.

Like dominoes, something installed on the mast could upset the placement of everything else. Holes cut in a mast must maintain a minimum spacing not only above and below each other, but also in relation to the holes on the opposite side of the mast. The halyards that lead to the cockpit need to be placed in the aft section of the mast. Halyards that are serviced at the mast winches have to exit and be oriented with the direction of rotation of the winch in mind. Details, details.

Pictures of our old mast, emailed to the mast builder, were a far better communication than a written description. Old pictures of our boat under sail and at the dock helped tremendously to refresh my own memory of what stood above us only a few weeks before. So many emails shot between the builder and us that I often wondered how he kept everything in order. We certainly didn’t, and at times we asked repetitive questions. Buzz Ballenger is a patient man.

All the specifications were entered onto a “cut sheet.” On paper, everything looked fine. With my fingers crossed, I okayed the cut sheet, sent a big check, and the mast went into production. We were never given an option on a mast shape; we took what was given us. The size of that spar was calculated by the mast maker after considering the yacht designer’s specifications for moments of inertia, rig geometry, rigging sizes, righting moment and minimum moments of inertia. Our consolation for the size and shape of that spar is that a cruising boat that wins most of the races in Majuro harbor carries the same mast and so does a friend’s 40-foot steel cruiser that has seen a lot of Pacific blue water action.

SHIPPING

The longest container available for shipping is 40 feet. At the mast factory, our 57-foot mast was cut into two sections fully assembled with a joining sleeve and scores of flathead screws then disassembled. The two sections were then wrapped in paper and padding before being inserted into a fortified circular paper tube for shipping. Packed in a separate box and strapped to a wood pallet was all of our new wire rigging with eye terminals swaged to the top ends. The lower ends I would cut to length and assemble with Norseman swageless fittings. Those fittings would attach to the new chromed, bronze turnbuckle assemblies.

MAST STEP

Our old, one-inch-thick aluminum mast step was a rusted disintegrated disaster. I had always sponged the bilge after every passage or rain shower, but bilge water had taken a toll on the step and was corroding the bottom end of the mast. This would not happen to our new rig.

Garolite 10, also called G-10, is a very hard composite used primarily as an electrical insulator. A one-inch thick block of G-10 is the perfect spacer for a mast shoe from bilge water. It is far better to pay the mast maker $25 to cut the hard Garolite to size with his water jet than to ruin a $50 carbide table saw blade. It is not suggested to use solid polyethylene as a mast spacer; under the great pressures the material can compress and “cold creep.”

The mast step shoe (which goes inside the mast base) supplied by the mast maker and sent to us in advance of the mast had two tiny cavities for draining water from the interior of the mast. Before assembling the mast step, I used an angle grinder to substantially increase the drain holes so they would not easily plug with debris.

Inside the mast, Ballenger had installed an extra thickness of aluminum at the spreader area to add side loading strength and to compensate for material removed for the installation of the spreaders. Aluminum at the mast base was also doubled. According to Ballenger, “The doubling gives the mast base more area so that it is less prone to ‘mushrooming,’ and since there is more material any corrosion that occurs has less structural effect. There are also extrusion welds in the mast extrusion that are part of the extrusion process. These vertical ‘welds’ are not always as strong or homogeneous as the surrounding metal and can sometimes split if the metal edge is point-loaded. The doubler helps to back this area up and avoid the problem.”

Only after the mast arrived did I find it was pure luck that I had perfectly positioned and bolted the mast shoe and step into the keel. There was no room for error. If I ever again bolt a new step for a different configuration mast, I will have the mast builder send a template of the mast base to aid in positioning the step so the mast sits plumb from the deck and flat on the step.

Six weeks after leaving the coast of California, our new mast and a mound of boxes arrived on schedule in Majuro. There are no yacht docking facilities in Majuro, and it was with great benevolence that our emergency was recognized by the manager of the local commercial fisheries dock, who allowed us to tie alongside that priceless concrete dock and use their electricity. Now, the real work would begin.

World cruisers Rebecca and Patrick Childress are now happily exploring remote Pacific islands and beyond. Read part two of their re-masting odyssey in the May issue of BWS.