Previously published in BWS by Brian Hancock.

For many years the only choice sailors had for fabric and engineering for their sails was cross-cut Dacron sails and for many years cross-cut Dacron sails suited them just fine. They were durable, aesthetically pleasing and not too costly, all good attributes in a sail. Things, however, have changed and these days there are myriad choices, Brian Hancock reviews the options in this multi part series.

For starters there are numerous kinds of Dacron all engineered to make different kinds of Dacron sails. Single ply, two ply, two ply leech only, bi-radial, tri-radial, you name it. Essentially what sailmakers have been trying to do is accommodate the different loads in a sail with an inefficient fabric for the job. Then along came a simple laminate that changed the way sails are engineered and made the engineering much more efficient by combining different weight fabrics in the same sail. These days there are membrane sails and not just simple membrane sails. Loadpath sails that are built using space age fibers developed for the defense industry and adapted for the sailing industry. It’s confusing and made more so by over enthusiastic sailmakers all touting their product as the best way to do things. Let’s step back and in this two part article really dig deep and try to understand what it is you need, what it is you are getting, and what’s right for you not only for your budget, but also for the kind of sailing you do.

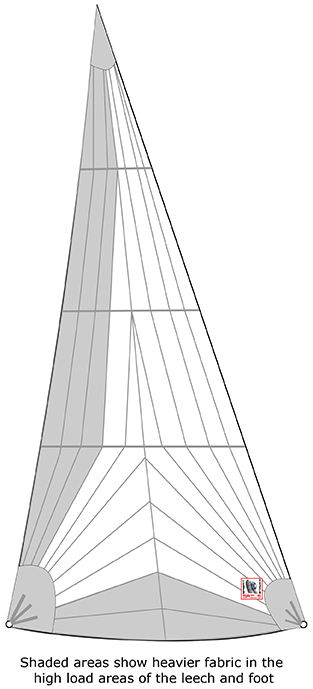

Tri radial genoa. The shaded areas show heavier fabric in the high load areas of the leech and foot

SAIL LOADS

A good place to start is by taking a closer look at what sail engineers are trying to accomplish. There are different loads in a sail and they change as the point of sail changes. For example let’s take a blade jib sailing upwind. Most of the load on the sail travels from the jib sheet through the clew patch and pretty much straight up the leech of the sail toward the head. These loads are quite substantial presuming you are using your blade in appropriate conditions. There is very little load on the luff and in the body of the sail close to the luff. As soon as you ease the sheet and bear away the load path changes and goes more toward the middle of the sail. It’s also substantially reduced and the further you sail off the wind, the less the load.

The goal for a sail designer is to build you a sail that is as light and as strong as possible for the expected conditions. Light sails are easier to handle and definitely easier to set and trim. It’s also important to keep the weight down so that you don’t have a lot of extra weight at the top of the mast where it exacerbates the heeling and pitching moment of the boat. This is not a big deal on a short daysail, but over the course of a long passage excessive heeling and pitching is fatiguing on the crew.

When the sail engineer comes to design this sail he calculates the maximum load along the leech and uses that number to decide what weight fabric to use for the sail. If the customer wants a cross-cut Dacron sail he is going to get a sail that is engineered perfectly for the leech load, but one that is overkill for the rest of the sail. As just pointed out the loads are substantially less along the luff and in the body of the sail. There is, however not much he can do about it. The fabric is run across the sail from leech to luff. In some cases, especially on bigger boats, he can design the sail with a lighter fabric and add a second ply along the leech and foot. This adds to the cost but reduces the overall weight of the sail.

HOW SAILS ARE CREATED

HOW SAILS ARE CREATED

The fabric itself is also engineered differently for different types of sails. A high aspect sail like a blade jib will require a fill-oriented fabric whereas a low aspect sail like a genoa will be made from a more balanced fabric. To understand the difference let’s take a quick look at the basics of woven sailcloth. In a woven fabric there is the warp and the fill. The warp refers to the yarns running the length of the fabric while the fill refers to the yarns running across the fabric. Another name for the fill is weft, but most sailmakers and sailcloth manufacturers prefer to use the more modern name. A fabric engineer can design a fabric to be warp-orientated by using heavier yarns running the length of the fabric or he can design a fabric to be fill-orientated by using heavier yarns along its width. Balanced fabrics, as their name implies, are equally balanced between the warp and fill so the fabric will exhibit equal strength in both directions. Continuing with the blade jib as an example, the fabric that will be used will have most of its strength in the fill (across the fabric) which is great because the load up the leech will fall directly onto the stronger yarns running across the fabric.

Some cloth manufacturers make a fabric that is warp oriented and can be used to make radial sails out of Dacron. To understand the difference between a fill oriented fabric, which is the most common, and newer warp oriented fabrics you need to understand what crimp is. During the weaving process the fill yarns are shot across the fabric by the shuttle and they are laid down absolutely straight. The warp yarns, however, have go over and under the fill to form the weave. They are pushed up against the fill yarns by a piece of equipment called the beater. The problem is this. As soon as a load comes on the fabric the warp yarns try to straighten out and the result is stretch. You can’t have it any other way. With a woven fabric you are going to have crimp and therefore you are going to have stretch. Some fabric makers have now figured out how to weave sailcloth where the warp yarns remain straight and the fill yarns are crimped and this is the fabric that can then be used to make radial sails. The load in radial sails will go onto the uncrimped warp yarns which is what you want.

LAMINATED SAILS

Laminated sails were introduced three decades ago and have become the way to go for many cruisers. The initial problems associated with delamination have mostly been fixed with the introduction of better adhesives and more modern ways of manufacturing sailcloth. A laminated sail allows you to build either a cross-cut or a radial sail, but most are used to build radial sails. Let’s examine a basic laminate. At the heart of a laminate is a mylar film which, being extruded rather than woven, is there to support any off-threadline (bias) stretch. It’s usually encapsulated between a variety of different scrims. This is where the engineering comes in. A basic cruising laminate will have one or two scrims laid down at different angles to absorb different loads. The scrims can be a basic Polyester or something more exotic and we will get into the exotic fibers shortly. The outer layers of a laminate are usually light polyester taffetas that have been treated with anti-mildew and anti-UV additives. All the layers are then placed under enormous pressure with heat added to bond them as one.

The real advantage of a laminate, other than the fact that it’s a lot lighter and stronger for the same strength and stretch resistance as Dacron, is that you can use the fabric to build a radial sail, either a bi-radial or a tri-radial sail. This way you can use fabrics of different weights in the same sail. You can have heavier fabric in the high load areas like the leech and foot and a lighter fabric in the body and along the luff of the sail. The problem that sail designers were having with cross cut sails just got solved and the result is a much lighter sail that is just as strong and as stretch resistant.

For a sail designer laminates are a gift because you are not limited to only a few layers and only to polyester fibers. You can have a fabric engineered that has multiple layers with each layer designed to accomplish a specific task. And you can mix and match fibers using a more exotic (read more expensive) fiber as the principal load bearing yarn and then back it up with less expensive fibers in the lesser roles. It’s all about engineering, both the sail and the fabric, and here is what you as a sailor need to understand. With sails, like most things in life, you get what you pay for. If the fabric has multiple layers and incorporates exotic yarns then you are going to pay extra, but you are going to get a much better sail. It will perform better over a longer period. I like to say that you should measure the life of a sail by how long it holds its shape and not just by how long it holds together.

In the second part of this series we will look at the different fibers that are currently being used to make cruising sails and examine their benefits as well as some of the drawbacks that limit their use in sailmaking. We will also look at a growing trend in cruising sails; membrane sails. These sails were once the exclusive domain of the racer but increasingly cruisers are turning to membranes to increase performance and add a touch of class to their boats.

Brian Hancock is a sailmaker, author, lecturer and veteran offshore sailor and racer. He lives in Marblehead, Mass.