Twelve years in their circumnavigation, the authors offer their expert view of what products aboard their boat they can recommend, or not (published Fall, 2019)

Fortunately, this year while sailing the world and the south east coast of Africa, on our Valiant 40, Brick House, we had only one product failure, some good successes and some promising equipment to install.

MILANO FAUCET

Our Moen, plastic, galley faucet had been with us for 12 years. It looked terrible though as the once white plastic had turned a nicotine yellow. After installing new water tubes to the galley, it was time to also install a new faucet. We went to an upscale mall in the largest city in Tanzania and bought the most expensive “stainless steel” faucet on display. The new faucet even passed our magnet test to make sure it was not chromed, common steel. The brilliant stainless finish certainly outshined our old faucet. But what a joke. Within two months the faucet was covered entirely by rust and corrosion. It still functioned, but it looked like it had been installed when this boat was built in 1976.

We contacted Milano Company, hoping for warranty coverage, but they told us that the faucet was not a Milano faucet even when we sent photos of the Milano name on the faucet. We then sent the credit card receipt and a video of the entire rack of Milano faucets in boxes at the store, with the salesman handing us our new faucet in the box with Milano clearly printed on it with all the Milano faucets in the background. They then refused to respond to any of our emails!

Moen no longer makes white plastic kitchen faucets, from what we can see. We will try a high-end Moen and see how it fares on our sailboat, which is really not any different of an environment than any other seaside cottage.

ALPENGLOW LIGHTS

ALPENGLOW LIGHTS

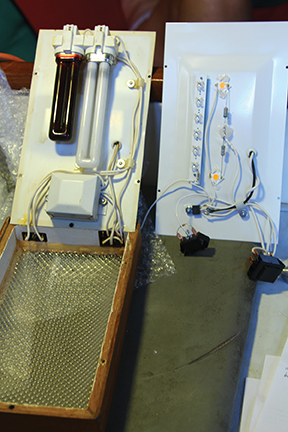

My grandmother used to say how streetlights in Chicago went from kerosene to gas to incandescent, in her time. Such a fast, modern, transformation. On our sailboat, we saw some of our incandescent light bulbs get swapped for the very efficient, Alpenglow Compact Fluorescent bulbs, and then years later, those bulbs were swapped for the amazing, low amperage, very bright, Alpenglow LEDS. The LEDs were installed over three years ago and they are still working perfectly. To make that swap, we ordered the Alpenglow conversion kits. The kits include a new back plate, attached red night light, white lights, wiring and new switches. We did the soldering and conversion ourselves but if one is not familiar with tight soldering, it would be far easier and secure to just send Alpenglow the existing units and let them do the upgrade, and retain the warranty. (www.alpenglowlights.com). The cost is only $10 more per unit for Alpenglow to do the work. That is a very good deal.

Our upgraded Alpenglow overhead lights have a high-low switch for the red light and a similar switch for the white light. On the low power setting for the white light, it draws 0.25 amps. That is plenty bright in our cabin or cockpit. Rarely do we use the high setting, which draws 0.5 amps and is about a 33 percent energy savings over the old bulbs but we get light that is 30 percent brighter. Even the old CFL bulbs rarely needed attention but the new LEDs are projected to last 50,000 hours, about 25-to-30 years. With the modern advancements in LED technology, the new Alpenglow lights are the same warm white color as before.

The LED has been such a positive upgrade that now, in some dodgy anchorages, we leave the cockpit Alpenglow on all night to discourage thieves. This upgrade has been a very good, maintenance-free investment and simply keeps on working.

MAGGI ANCHOR CHAIN

MAGGI ANCHOR CHAIN

It was past time to get new anchor chain. Our anchor chain was at least 25 years old, had been re-galvanized twice and was now so rusty, I could not trust its strength in a strong blow. The problem was that we were in Thailand and Malaysia for a long time, where Chinese chain dominated the market.

There can be huge differences in longevity from one brand of chain to another, even when the chain grade and strength ratings are comparable. Chinese chain is most often not marked to indicate the manufacturer, or for anything else, so there is no indication of its quality without testing each piece. According to Practical Sailor magazine, some Chinese chain they tested is excellent while other Chinese chain is very unreliable. We decided to order well in advance and have chain delivered to us in Richards Bay, South Africa. We went with a long-standing Italian company known for superior quality, Maggi Chain USA. Maggi chain is well known for its strength and elasticity and its secret galvanizing process. While many European companies have turned to importing chain from China, Maggi continues to produce its own galvanized G40 and G70 (marketed as Aqua 4 and 7).

We had been getting by all these years with 5/16-inch chain, but specifications for our weight of boat call for 3/8-inch chain. We did upsize to 3/8-inch and bought a new gypsy for our Lofrans windlass. Our Maggi chain is stamped about every 3 feet with “MCIT”, which stands for Maggi Chain Italy. Sometimes this same chain will be stamped with “A4”, which stands for Aqua 4. If a chain is not stamped, how would a cruiser know for sure who made it? Another thing to look for is a “Cert”. When a retailer sells an anchor chain, he should be able to supply to the customer a “Cert”, that is, a certificate to show the chain has been recently tested and meets the minimum stated specifications. If this cannot be made available, I would proceed with great caution.

PROPSPEED ANTIFOULING

I have never been able to keep antifouling on any propeller that was installed on Brick House no matter what material the prop was made of. Antifouling quickly disappeared, which meant the beginning again of the biweekly chore to scrub the marine growth from the prop and drive shaft. In the 85-degree tropical water to which we are accustomed, the work was not terribly uncomfortable. However, there are frigid South American waters in our future, so I want the prop and shaft cleaning to be a quick “in and out” operation.

We have had Propspeed, which is a silicone coating, on our propulsion system in the past and it did what the advertising said it would do. We were very satisfied. The application is a very precise process of sanding, cleaning, etching, applying primer and then the final application of the clear silicone coating. The clear coating is not antifouling but an ultra-smooth surface that marine organisms have a very difficult time attaching to. If organisms do settle in the first year of application, I have been able to easily brush them off with a soft rag, and I would do this every two to three weeks to be on the safe side. As the Propspeed ages, a little more agitation is needed to brush the critters away.

The manufacturer of our Kiwiprop suggested that it is not necessary to prime the Zytel blades before applying traditional antifouling or Propspeed. I have learned to ignore that advise. With a Kiwiprop, however, an applicator must be careful not to build up any material in the area of swing of the blades’ trailing edge, as this could inhibit their forward-to-reverse function.

I can’t imagine a young-kid boat yard worker doing the application of Propspeed, correctly. Proper progression and timing of the application process is a fluid motion which leaves no room for taking a lunch or smoke break. Having a countdown timer during the application is useful to make sure one stays within the narrow window for proper adhesion between cleaning, priming and applying the finish coat. Propspeed is another great product made in New Zealand by Oceanmax.

TIDES MARINE SAIL TRACK

TIDES MARINE SAIL TRACK

Except for being wrapped up in our bent and mangled mast, during a dismasting, our previous Tides Marine Sail Track (www.tidesmarine.com ) was in great shape and served us well. That was in 2011, the same year our new mast went up, and so too the new Tides Marine Sail Track. So now, that track is eight years old.

Since we had been sailing all of that time in the harsh sun of the tropics, our TMST is showing some ultra violet sun etching. Now, we are hauled out in Africa, going through all the boat systems and replacing many things, including the TMST, well before their expiration date so we can have a safe adventure crossing the Atlantic and rounding of South America.

The Tides Marine Sail Track is made of UHMW (ultra-high-molecular weight polyethylene) and is installed by simply sliding it up the existing mast groove and securing in place with a stop at the top and bottom.

On our 40-foot sailboat, I much prefer the Tides track, with its 316 sail slides, over roller-bearing cars. Although those systems are easy to raise, there is so little friction that everything comes crashing down, sounding like something is going to break, unless one constantly has a hand on the halyard with a wrap around a winch. With the TMST and the stainless slides, I can let the main halyard fly and the main comes down at a measured clip. The last several feet of sail triangle stays suspended just above the boom until it is ready to be flaked and then is easily pulled down.

The track comes in 125 different shapes to fit a variety of internal luff grooves as well as several external track shapes. This product has always proven to be a good investment on Brick House.

COPPERCOAT ANTIFOULING

COPPERCOAT ANTIFOULING

We have never been satisfied with any antifouling paint we have applied to the bottom of Brick House. Self-ablative paints don’t self ablate. Medium hard paints attract soft, medium and hard marine growth. Every antifouling paint we have used, far in advance of expectations, requires going over the side with our hookah gear and hand scrubbing the bottom. Even exposing new paint, it seems the toxins have leached out and marine growth soon reattaches itself. Our hookah and scraper have proven to be the best antifouling/defouling gear.

Since there is no avoiding going over the side to clean the bottom, we will take a new approach, to make bottom cleaning much easier. Copper Coat is becoming well known, and if applied properly, is getting positive assessments.

Coppercoat is the combination of a specially developed two-part epoxy resin and 99 percent pure copper. Each liter of Coppercoat contains 2kg of ultra-fine copper powder. On immersion, sea water attacks the exposed pure copper, causing the formation of cuprous oxide. This highly effective anti-fouling agent deters growth until the surface degrades further to become cupric hydrochloride. This final copper form is highly unstable and is washed away by the movement of the yacht, thereby removing any accumulating silt or slime. This automatically reveals a fresh copper-rich surface whereby the process recommences. But, it is the “washed away by the movement of the yacht” promise I am not counting on. Yachts can sit for a long time and accumulate a huge amount of growth and some yachts just don’t reach surfing speeds to knock anything but a rusted piece of rigging loose. I hope I am pleasantly surprised and won’t have to spend much time in the water wiping the Copper Coat with a soft towel to remove marine growth. But if so, this will be a big improvement over having to use scrapers and scrubby pads which would take me at least two hours of underwater time to clean conventional antifouling.

AMT COMPOSITES

AMT COMPOSITES

While in the U.S., I always used West System epoxy. Now that we are hauled out in South Africa, there are no familiar brands of epoxy for sale at the local marine store. I had to buy one-liter bottles of repackaged resin and hardener, which had little more than the price tag for markings. I found out the hard way that no sales clerks knew the proper mixing ratio. What a disaster… my fiberglass layup never hardened properly and I had to spend excruciating effort to strip the uncured layers off my previously solid work. Quickly I had enough of this repackaged, non-marked, who-knows-what brand of epoxy, and needed to find the good stuff.

Asking the boat yard contractors where they buy reliable epoxy, they all responded that they use AMT Composites (Advanced Materials Technology trading as AMT Composites) which has offices in Cape Town, Durban and Johannesburg. AMT supplies whatever one needs for building anything from composite airplanes to making a composite coffee table, to luxury boat building. AMT distributes Gurit formulated products – formerly SP Systems – which are manufactured in the U.K.. This is now what I have been using for general fiberglassing and repairing on Brick House. From all indications, this particular resin SP106, is equal to the West System 105 resin. The Gurit resin will also be used to rebuild all the craters in our hull that were created when I ground out old blisters that were initiated back in 1976, when this boat was built with bad fiberglass resin. The builder switched to a cheaper resin supplier and got what he paid for –this is sounding familiar–and now we are paying for it in repair labor and materials. When we need more supplies, whether resin, cloth or Peelply, I simply call in the order and they ship it to us here in Richards Bay. We could also buy it from one of the local yard contractors.

The people at AMT provided some excellent technical advice when we initially contacted them to be sure we were buying the best materials for our particular job. The one thing about the AMT supplied resin is that they do not make available metered pumps so each batch of resin and hardener must be weighed on a scale. Every boat owner who plans to do work on their boat in South Africa needs to have the AMT website loaded on their computer. (AMT is kind enough to give us a discount on our supplies for mentioning them in this article.)

BLUEWATER BOOKS & CHARTS

BLUEWATER BOOKS & CHARTS

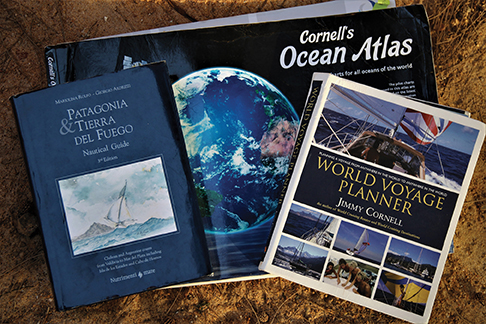

There is nothing like having a large-scale paper chart to see where a boat has been and where it is going. The super-wide view, also gives a spatial awareness that no chartplotter screen can match. We ordered a paper chart of the entire Atlantic Ocean from Bluewater Books and Charts (bluewaterweb.com). That chart will be folded flat and live under the Plexiglas of the chart table. We will be able to quickly plot the location of fellow cruisers and keep track of our own wanderings.

Additionally, as we start the fourth quarter of our circumnavigation, we have found that despite the plethora of digital information, a printed paper cruising guide, one that we can highlight and scribble notes in, is still our preferred way to organize routes and anchorages ahead. We stocked up with the Atlantic Circuit and Patagonia & Tierra Del Fuego Nautical Guide, for the next year or two of travel.

Bluewater Books and Charts has been in business for more than 30 years and offers the single greatest selection of paper and electronic charts, cruising guides, marine books and publications, software, flags and instruments available for sailors like us. It’s nice to have one central location for everything offered, who can reliably ship around the world to us.

We have made KAP files (Google Earth charts) for every possible stop along the way, downloaded the Ovitalmap Bing satellite charts on our iPad, and have gotten new Navionics and Jeppesen CMap chart chips for both the Raymarine chartplotter as well as the iPad; we will update them again electronically just before we leave.

This year, for the first time, we purchased the Navionics PLATINUM+ Satellite/photography/nautical charts for South America for the chartplotter, instead of just the Navionics+ chips we have used in the past. This will be our first look at the Platinum+ charts, running them on the newly updated Raymarine Lighthouse software that brings our slightly dated chartplotter up to the current look and feel of Raymarine’s latest models. This is very exciting considering the advances Raymarine constantly makes to their technology! We will now go into anchorages with full satellite images and photography on the chartplotter (still our favorite source), and we will have all the paper books and information we need in one central location without even having to turn on a computer.

Patrick and Rebecca Childress sailed away from Rhode Island to spend 4 years cruising. That was now, 12 years ago. The have sailed ¾ of the way around the world. They are hauled out in South Africa, revamping their boat in preparation for crossing the Atlantic to Uruguay. How far south they get will depend on how well the cold weather treats them. Join their “how to” channel on YouTube, www.youtube.com/patrickchildress.