Re-powering a 36-ketch with an electric motor (published November 2014)

When my diesel engine’s exhaust manifold, raw water header tank, and other critical and expensive systems collectively showed terminal stages of corrosive failure in late 2010, I was faced with a very costly decision: purchase new parts for the aging engine and spend the money for an overhaul right then, or sell the well-regarded workhorse at a quite-fair value and purchase a new power plant. After weighing the options, my personal thoughts, and financial considerations, I decided to install an electric propulsion system from Electric Yacht. Here is the story of the engine conversion and some of my observations after a few thousand miles.

DIESEL VS ELECTRIC

Electric propulsion for boats is not new. Thomas Edison famously made one of the first electric boats in 1903, and the vast majority of submersible craft have been electric powered—either in total or as a hybrid diesel/electric drivetrain—for decades. Electric power has the advantages of being nearly silent, exceptionally clean, highly reliable and vastly less expensive from an operating cost and maintenance perspective over internal combustion drivetrains. Electric power is a perfect companion to a sailboat because, like the act of sailing itself, it is silent, renewable and clean. There is no oil to change, no coolant to worry about, no recirculating saltwater system to clog, no impellers to break and no extra through-hulls to punch in your boat.

It can charge through solar, wind, high-efficiency generators, series-hybrid diesels, or, in some cases, via the sailing motion of the boat spinning the propeller at sufficient speeds—a form of regenerative charging similar to hybrid cars. A complete system weighs about the same as a comparable diesel with full tanks, but the batteries can be located nearly anywhere that the weight serves the boat. And unlike diesel, which is consumed, the batteries can be used in place of ballast, thus making the entire boat lighter and more nimble while freeing up internal storage space. The motor itself can be lifted without a crane by a moderately fit person for the very rare situations in which maintenance or prop shaft access is needed. All that, and the bilges stay spotless.

Compared to their many advantages, the only main concern with electric motors is that they are range-limited compared to gasoline or diesel engines. Batteries simply do not store the same amount of energy per volume or mass as liquid fuel, so recharging needs to occur more frequently per mile motored. For sailors who sail more than motor, and are willing to wait out a lull in the wind when offshore, this is no big deal. The range is more than adequate to get the boat to a safe position when the wind dies and you’re caught inshore in a current, for instance. But it’s not a solution for those whose plan for their sailboat involves significant and long-distance usage of the motor. For longer-range solutions, most electric-motor sailors turn to a series-hybrid power train with a generator (diesel or gasoline) providing electrical power to the motor, giving extended runtimes and preventing flat batteries on arrival.

I was charging my house bank with a 2kW “putt-putt” generator anyway, since it saves wear and tear on the diesel and provides more power than a high-output alternator would, so using this to charge the electric motor batteries at the same time was no problem. In fact, with the right controller I could run the electric motor at sufficient power to move my 16,000 pound boat at about three knots on the generator alone, if I needed longer range. A bigger generator would have allowed more power, but that wasn’t really the point for me.

Electric motors shine when the typical use of the motor is to get in and out of a harbor, on and off a mooring when sailing isn’t an option, or to get an extra smidgen of help when heading upwind to clear a point, or the like. They are like a breath of extra wind when you need it, the kick of an oar to turn the boat a bit more quickly and a helping deckhand to back that sail when you’re tied to the helm. They are instantly available, ready to work immediately and don’t suffer when you apply short bursts of power and shut them off again. They don’t heat your interior, don’t deafen the person sleeping in the quarter berth, and allow your guests to have a reasonable conversation, even in the companionway. In fact, they probably won’t even know it’s on.

Electric motors shine when the typical use of the motor is to get in and out of a harbor, on and off a mooring when sailing isn’t an option, or to get an extra smidgen of help when heading upwind to clear a point, or the like. They are like a breath of extra wind when you need it, the kick of an oar to turn the boat a bit more quickly and a helping deckhand to back that sail when you’re tied to the helm. They are instantly available, ready to work immediately and don’t suffer when you apply short bursts of power and shut them off again. They don’t heat your interior, don’t deafen the person sleeping in the quarter berth, and allow your guests to have a reasonable conversation, even in the companionway. In fact, they probably won’t even know it’s on.

This suited me just fine, so I took the plunge. I sold the diesel for very nearly the same cost as the electric motor installation kit, so my only extra expense was the battery bank. I have heard that this is typical for other people as well—a diesel engine with a useable core, even if it needs some expensive extras, often sells for a pretty good chunk of change.

PREPARATION

To plan for a successful installation, I spent some time consulting with Scott at Electric Yacht and doing a lot of my own research. One of my main criteria was being able to use the different power sources—house bank, engine bank, solar, wind, generator—on my boat to provide house power as well as 120V AC easily and cleanly. I also wanted highly efficient and high powered charging devices to minimize generator runtime and get maximum power from it.

On the propulsion side, I wasn’t as concerned with maximum horsepower as I was with efficient cruising speed in calm or light winds and a reasonable compromise between battery space/weight and cruising range. I ended up choosing a 220AH battery bank and a 9.6kW motor, which we calculated would provide between five and 10 miles of total range depending on conditions, at a speed of about three knots, but be able to nearly reach hull speed in a pinch—albeit for a much shorter duration of time. Accompanying the motor and battery bank was a 25A charger which matched the 2kW output of my generator, a high efficiency DC-DC converter allowing me to run my 12V house system off the 48V engine batteries, and a 48V inverter providing 120V AC pure sine wave power to run heavy-duty power tools off the engine bank. This allowed me to get maximum use out of the various electrical options I had onboard, but was simple and redundant enough that if any individual system failed I was able to continue operating normally.

MAKING WAY

MAKING WAY

I knew that the electric motor’s needs and installation was sufficiently different from the diesel I was removing and warranted some significant effort in preparing the space. I’m glad I took the time to do this step first, as it’s much easier to access everything when the engine is gone. So I cleaned the bilge thoroughly, slapped a new coat of paint on everything and tidied up all the crusty wires in that compartment.

The first plan of action was to remove the old fuel tanks. I planned to store the batteries in the same location as the existing 40-gallon tanks, just above the keel and as low and central inboard as possible. After removing the fuel tanks, I then cleaned up the ugly fiberglass surfaces in the keel and bilge areas. The bilge got a fresh coat of epoxy barrier coat and white paint, while the keel area got some wooden cleats installed to mount the custom wooden battery tray. I took advantage of this time to replace the bilge pumps and service the bilge hoses and prop coupling as well.

With the engine bay and bilge clean, I turned my attention to the battery mounts. Eight Group 27 AGM sealed lead-acid batteries weigh a lot, and if the boat were to be thrown around or, worst case, inverted, I did not want them slamming around. So I put some serious effort into restraining them by building a mounting platform out of ¾ inch plywood that I epoxy coated for water and acid resistance. Cutouts on the side allowed for heavy webbing straps to be wrapped around the entire platform to strap the batteries in place. The whole thing was then bolted to heavy oak blocks that I glassed into the sides of the keel.

With the pallet of batteries placed in the keel, they were easily accessible, out of the way and firmly secured from all types of possible boat motion. I allowed room underneath them for cooling and water drainage from the forward parts of the boat, and adequate air circulation for venting of any gasses—AGM batteries typically don’t vent explosive gasses but I wanted to be on the safe side. While I was working on this plan, I decided to get the motor mounted to have it out of the way during the rest of the construction.

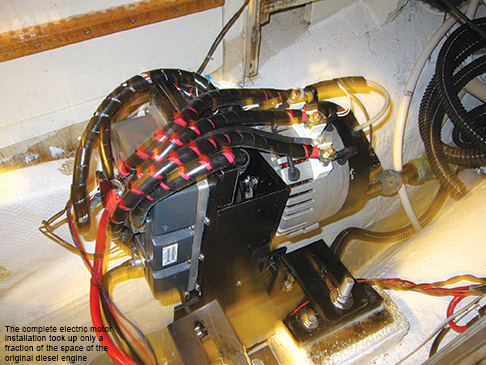

Electric Yacht supplies their motors with a custom mounting bracket that, in theory, allows for the motor to drop on top of many common motor mount platforms. Using a combination of adjustable angle brackets and a custom-made wooden offset, it wasn’t hard to bolt the three “legs” of the motor frame to the existing engine mount risers. I left the risers in place in case I, or a future owner, changed our minds about the electric installation, but it wasn’t necessary. The motor fit perfectly in place, and since it weighs so much less than the diesel, aligning it to the prop shaft was a cinch.

Instead of using a heavy coupling, a simple stainless collar with matching keyways goes between the shaft and the motor drive shaft. There is no transmission, since the motor can spin forwards or backwards on its own, and the simple single-belt reduction drive is quiet, reliable and extremely efficient. It also allows for adjusting motor rpm to prop speed to suit a range of prop diameters and pitches. This adjustment involves replacement of one or both pulleys, and can be done in about an hour using simple tools.

At this point I had the motor physically mounted, aligned and installed to the prop shaft. The battery tray was bolted in place, and the batteries were firmly strapped to their mounts.

CABLING & ELECTRICAL SAFETY

CABLING & ELECTRICAL SAFETY

The electrical power involved in a propulsion system is extremely powerful—48 Volts with up to 200 Amperes can routinely flow through this particular system at full motor power. This is nearly 10kW of power. As you can imagine, if the batteries can provide this kind of power routinely, they have the capacity to do significant damage in an instant if there are not circuit safeguards in place.

To minimize the voltage differences within the battery bank, I opted to go with a single series stack of 6-volt batteries, wired with the ultimate positive and negative terminals opposing each other at the end nearest the motor. Each battery is easily capable of melting a heavy-duty wrench and simultaneously starting a massive electrical fire if directly shorted, and each terminal in a series-connected string of batteries is a potential point of danger. To alleviate this, I wore insulating gloves and used insulated tools exclusively while working on the bank.

Wiring was handled very carefully and all terminals were capped off when not immediately in use or already connected. I connected the bank immediately to a massive 350A fuse, and then again to a safety cutoff switch. I connected them in this order because of the longer run required to put a switch within accessible reach. A fuse could be connected directly to the battery bank output whereas the closest place I could put a reachable switch was a few feet away.

After the disconnect switch, I installed the motor cabling as the instructions recommended, along with the chargers, converters and inverters. With so much extra space in the engine compartment, finding places for these devices was simple and made for very clean and easily accessible cable runs.

UNDER CONTROL

UNDER CONTROL

A throttle, much like any engine, controls electric motor drivetrains. But these are not the mechanically linked throttles you’re used to using with your diesel inboard, and there is no transmission necessary. The throttle is a simple “fly by wire” controller similar to a very durable, industrial-quality corrosion-resistant joystick that connects via a wiring harness to the motor controller. A remote LCD display takes the place of the dials and gauges for engine instrumentation and, like the throttle, can be mounted nearly anywhere convenient. I chose to fiberglass over the existing control spaces and throttle mounts and relocated the throttle somewhere much more convenient; right next to the wheel instead of down in the cockpit well. The display was likewise relocated to the aft cabin bulkhead, making it much more visible than being tucked away in front of the mizzen mast down in the footwell.

With the surfaces prepped, installing the controls took very little time at all. Everything was ready for the power on test and dock trials.

I’VE GOT THE POWER

With the boat firmly tied to the dock pilings, I first turned the battery disconnect on and checked that the display came to life. I then turned the key on and reveled in the absolute silence. The motor was there, active and ready to spin up at my command, but there was no idle noise, no rumble belowdecks and no indication of any kind other than the ready status on the LCD.

After another quick check that all was clear, the boat was secure, and nothing seemed amiss, I ran through the recommended throttle calibration routine, and then gradually applied power to the motor. A very quiet hum and the gentle wash of the prop were the only indications that I had done anything, but the boat began to gently strain against her lines. Satisfied that everything was working as expected, I made plans for a quick spin around the marina on a dead calm day.

I had expected that the motor would be at least as powerful as the diesel at full throttle, but I was surprised that the motor also spun up faster, providing more rapid torque. This made maneuvering with prop walk and tight turns much easier. The boat actually handled more nimbly in the tight quarters of the marina than before, and this thrilled me. I decided it was time to take her out and about the coast.

THREE THOUSAND MILES LATER

After singlehanding Aletheia 3,000 miles of coastal and offshore sailing with the electric motor, I have many observations. First and foremost, the engine is definitely a success. While there were some learning pains along the way as I worked to get a good match between the prop and the motor speed (by changing out gear ratio pulleys on the belt drive) and troubleshot some initial teething issues with charging, once we got those out of the way it has been a reliable and trouble-free companion.

The fact that it is range limited definitely factors into my sailing, but only insofar as I determined from the beginning that I was going with a smaller battery bank, thus consciously accepting a short motoring range. With a clean bottom the range is still absolutely enough to close the coast against a gentle current in a dying wind, traverse a narrow arm with fluky and variable winds, or any of the other situations in which even purists would find themselves reaching for a pair of oars. In every case that the motor would not have been sufficient, it was very clear at the outset that I could be sailing or would be wise to stand off, engine or not.

So far, with this motor I have made a solo journey involving both significant coastal and offshore passages from the Gulf of Mexico to Canada. I went through a dismasting offshore during a part of the sail and successfully made it back—a story for another time—and in no way did the lack of an inboard diesel prevent my safe return. When I re-rigged my boat I had the option to re-power at the same time, and I chose to continue with the electric motor.

My electric motor effortlessly assists my solo and shorthanded sailing in innumerable ways and brings a purity and enjoyment to sailing—smoothing out some of the bumps, so to speak. In short, having it onboard maintains my philosophy of simplicity, silence and sailing in harmony with nature. It also puts a big grin on my face when my friends never realize I touched the throttle.